LSZH double spiral cone mixer

S

UMMARIZE

SUMMARY

Reliable supplier of drying equipment users

UMMARIZE SUMMARY

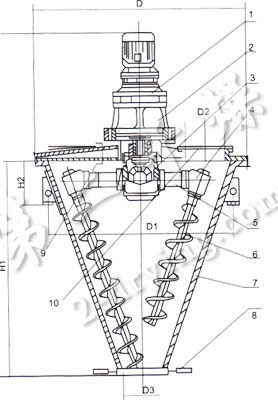

The mixing part of the double spiral conical mixer is two asymmetric spiral cantilevers. When working, the cantilevers rotate around their own axis (rotation), and at the same time, they also make planetary motion (revolution) around the central axis of the conical container near the cone wall surface with the help of the rotation of the rotating arm. Through the common rotation and rotation of the screw, the material is lifted repeatedly, resulting in shear, convection, diffusion and other composite movements in the cone, so as to achieve the purpose of mixing. Standard products are divided into double motor drive (type A) and single motor drive (type b).

P

ARAMETER

PARAMETER

Reliable supplier of drying equipment users

ARAMETER PARAMETER

| Model / item | Full volume(M3) | Loading coefficient | power | size(mm) | weight |

| LSZH-0.3 | 0.3 | 0.4-0.6 | 2.2 | Φ920×1920 | 550 |

| LSZH-0.5 | 0.5 | 0.4-0.6 | 3 | Φ1140×2320 | 600 |

| LSZH-1 | 1 | 0.4-0.6 | 4 | Φ1480×2895 | 1200 |

| LSZH-1.5 | 1.5 | 0.4-0.6 | 5.5 | Φ1633×3210 | 1350 |

| LSZH-2 | 2 | 0.4-0.6 | 5.5 | Φ1816×3495 | 1500 |

| LSZH-3 | 3 | 0.4-0.6 | 7.5 | Φ2040×3760 | 2300 |

| LSZH-4 | 4 | 0.4-0.6 | 11 | Φ2250×4425 | 2520 |

| LSZH-6 | 6 | 0.4-0.6 | 15 | Φ2548×4940 | 3000 |

| LSZH-8 | 8 | 0.4-0.6 | 18.5 | Φ2780×5360 | 4500 |

| LSZH-10 | 10 | 0.4-0.6 | 22 | Φ3018×5815 | 5500 |

| LSZH-12 | 12 | 0.4-0.6 | 22 | Φ3204×6100 | 5900 |

| LSZH-15 | 15 | 0.4-0.6 | 30 | Φ3442×6540 | 6600 |

| LSZH-20 | 20 | 0.4-0.6 | 37 | Φ3805×7420 | 9800 |

| LSZH-25 | 25 | 0.4-0.6 | 37 | Φ4086×7800 | 10200 |

| LSZH-30 | 30 | 0.4-0.6 | 45 | Φ4330×8200 | 11500 |

P

rocess

PROCESS

Reliable supplier of drying equipment users

rocess PROCESS

1. The jacket can be added outside the mixer barrel for heating and cooling. The material can be cooled or heated by injecting hot and cold medium into the jacket. Generally, the cooling water is pumped into industrial water, and the heating can be connected with steam or electric heating heat transfer oil.

2. The liquid adding and mixing can be realized by passing through the spray pipe at the intermediate shaft of the mixer and connecting with the atomizing nozzle. By selecting a specific material, acid and alkaline liquid materials can be added to mix the powder and liquid.

3. The pressure strength cylinder cover can be made into a dome, which can reduce the residue and facilitate cleaning, and can improve the pressure strength of the mixer cylinder. This setting is often used when the mixer cylinder pressure is required.

4. The negative pressure feeding can make the mixer cylinder into a negative pressure bin in a specific process, and use a hose to suck the dry materials with good fluidity into the mixing bin for mixing, so as to avoid the residue and pollution in the material feeding process.

5. The standard equipment of discharging mode generally adopts the quincunx "dislocations valve", which is closely connected with the bottom of the long screw to effectively reduce the dead angle of mixing. The driving mode can be manual or pneumatic; according to the user's needs, it can also be equipped with butterfly valve, ball valve, star discharger, side discharging, etc.

C

ONSTRUCTION

CONSTRUCTION

Reliable supplier of drying equipment users

ONSTRUCTION CONSTRUCTION

1.电机

2.减速机

3.分配箱

4.传动头

5.转臂

6.旋转轴

7.筒体

8.出料阀

9.喷液装置

10.进料口