Special belt dryer for silica gel

S

UMMARIZE

SUMMARY

Reliable supplier of drying equipment users

UMMARIZE SUMMARY

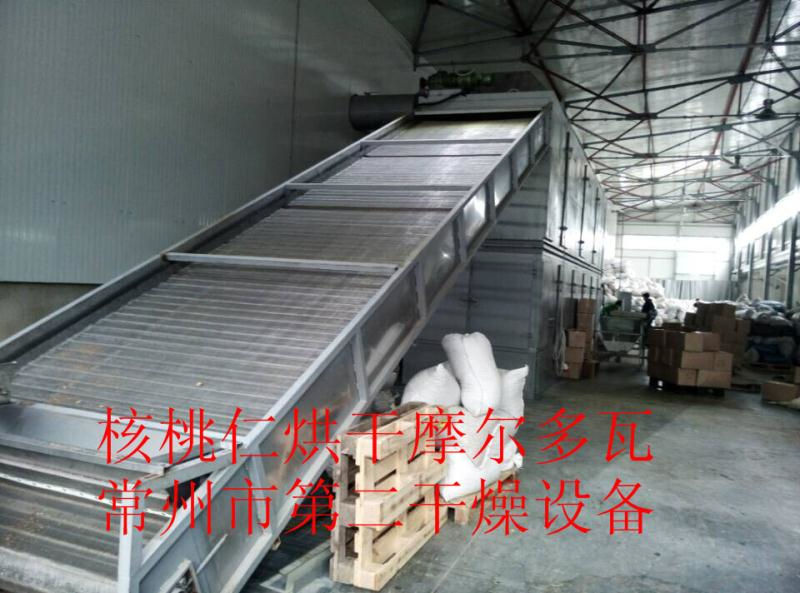

According to the water characteristics of silica gel, it can be known that it is mainly internal adsorbed water, so the drying process is relatively slow. In the drying process of silica gel, it is necessary to ensure that not only the drying temperature, but also the retention time can meet the requirements, otherwise the damage of silica gel will be serious if the drying speed is too fast. In the whole drying process of silica gel, the temperature in the front preheating section is slightly lower, and the mesh belt speed is faster, while that in the back drying section and heating can be increased, and the mesh belt speed is lower.

Three net belt dryers are connected in series to form preheating section, water evaporation section and material heating section. Due to the particularity of silica gel dryer, the temperature of the first dryer should not be too high, the control temperature is between 80-100 ℃, the mesh belt speed can be slightly faster, the temperature of the second dryer can be properly increased, the control temperature is between 100-120 ℃, the operation speed of the mesh belt can be properly reduced, the temperature of the third dryer can be gradually increased, the control temperature is between 120-140 ℃, the transportation of the mesh belt The line speed is lower.

When the silica gel just enters the belt dryer after granulation, there will be some free water on the surface of the material. At this time, blow it with hot air in the front of the dryer, and then remove most of the free water. At the same time, the material begins to preheat. Because the air humidity is high, the mixing temperature of the first several units just entering the belt dryer is low.

With the drying process, the water on the surface of the material evaporates rapidly. As the heat is absorbed by the material, the heat and mass transfer is carried out, and the water in the material is gradually transferred to the surface and evaporated. At the same time, with the further drying, the water content of the material decreases, the drying speed slows down, and the particle diameter of the material shrinks. In this stage, the temperature of the hot air can be increased appropriately (the unit mixing temperature can be controlled by the steam solenoid valve), and the operation speed of the mesh belt can be reduced appropriately. At this time, the temperature of the material will gradually increase until the final water content requirements are met.